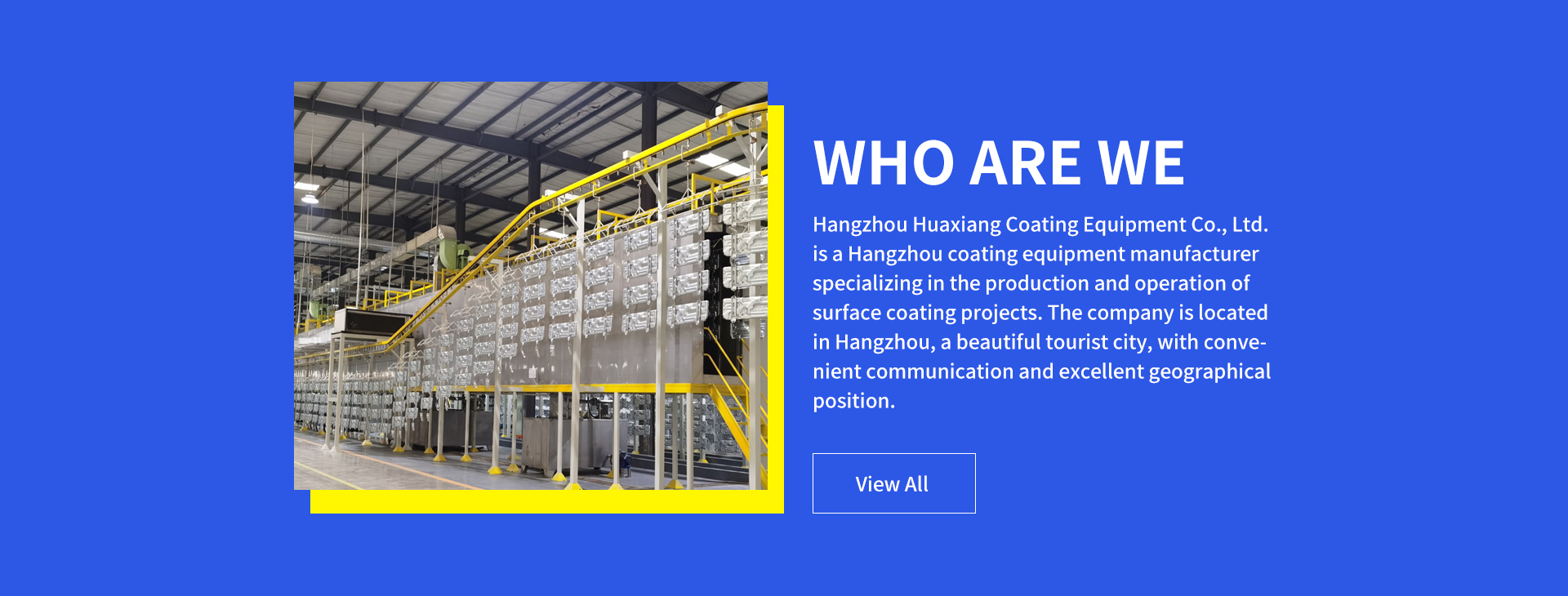

1. Industrial Powder Coating Spraying Line Overview and Components

An Industrial Powder Coating Spraying Line is a fully integrated system designed for large-scale, high-efficiency coating operations. Key components include a pre-treatment station (cleaning, phosphating), electrostatic spray booth, conveyor system, curing oven, and powder recovery unit. Advanced lines feature robotic arms, IoT-enabled controls, and real-time monitoring tools to ensure precision, minimal waste, and consistent finishes on metals, plastics, and ceramics.

2. Applications of Industrial Powder Coating Spraying Line

These lines are pivotal in automotive manufacturing, aerospace, appliance production, and architectural industries. They coat car bodies, aircraft components, household appliances, and structural steel. Suitable for materials like aluminum, steel, and heat-resistant polymers, they deliver durable, corrosion-resistant finishes ideal for demanding environments.

3. Pricing of Industrial Powder Coating Spraying Line

Costs range from 100,000forsemi−automatedlinesto2 million+ for fully robotic systems. Entry-level models suit mid-sized factories, while high-speed lines with AI integration cater to large-scale production. Factors like throughput (e.g., 500–5,000 parts/day), energy efficiency, and brand (e.g., Durr, GEMA) significantly impact pricing.

4. Proper Usage of Industrial Powder Coating Spraying Line

Pre-treatment: Degrease and pre-treat surfaces for optimal adhesion.

Automated Spraying: Program robots to apply powder uniformly.

Curing: Bake parts at 350–450°F for 10–30 minutes.

Recovery: Recycle 90%+ excess powder via cyclones.

Maintenance: Clean spray guns daily and calibrate sensors weekly.

5. How to Choose an Industrial Powder Coating Spraying Line

Capacity: Match line speed (e.g., 200 vs. 2,000 parts/hour) to production needs.

Flexibility: Opt for modular designs adaptable to varying part sizes.

Energy Efficiency: Prioritize insulated ovens and low-power robots.

Compliance: Ensure adherence to OSHA and EPA regulations.

6. Safety Precautions for Industrial Powder Coating Spraying Line

Use explosion-proof equipment in powder-rich zones.

Install emergency stop buttons and fire suppression systems.

Train operators on handling high-voltage components.

Store powders in temperature-controlled, ventilated areas.

7. Design Rationale of Industrial Powder Coating Spraying Line

Modern lines emphasize automation, sustainability, and scalability. Robotic arms ensure precision, while energy recovery systems reduce costs. IoT integration optimizes powder usage, and stainless steel construction enhances durability in harsh conditions.

8. Q&A on Industrial Powder Coating Spraying Line

Q1: What is the ROI of an automated line?

A: High-volume producers achieve ROI in 2–4 years via reduced labor and waste.

Q2: Can lines handle multi-layer coatings?

A: Yes, with precise temperature control and compatible powders.

Q3: How does powder recovery reduce costs?

A: Recycling 85–95% of overspray cuts material expenses by 40%.

Q4: Are these lines eco-friendly?

A: Yes, zero VOC emissions and powder recycling meet sustainability standards.

Q5: What training is required for operators?

A: Training in robotics, electrostatic safety, and maintenance protocols.

This guide provides actionable insights into Industrial Powder Coating Spraying Lines, empowering manufacturers to enhance productivity, quality, and safety in coating processes.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com